Products

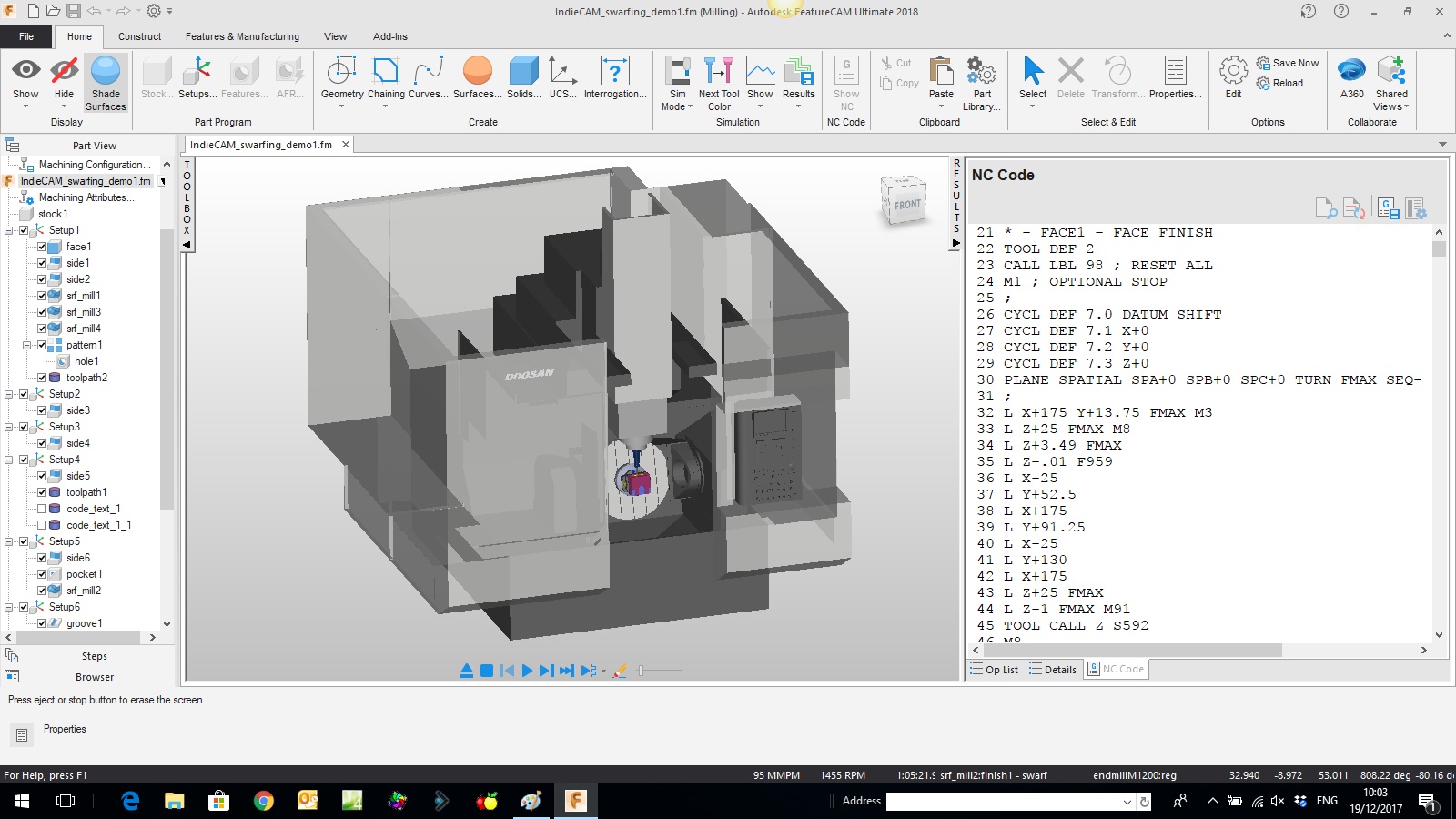

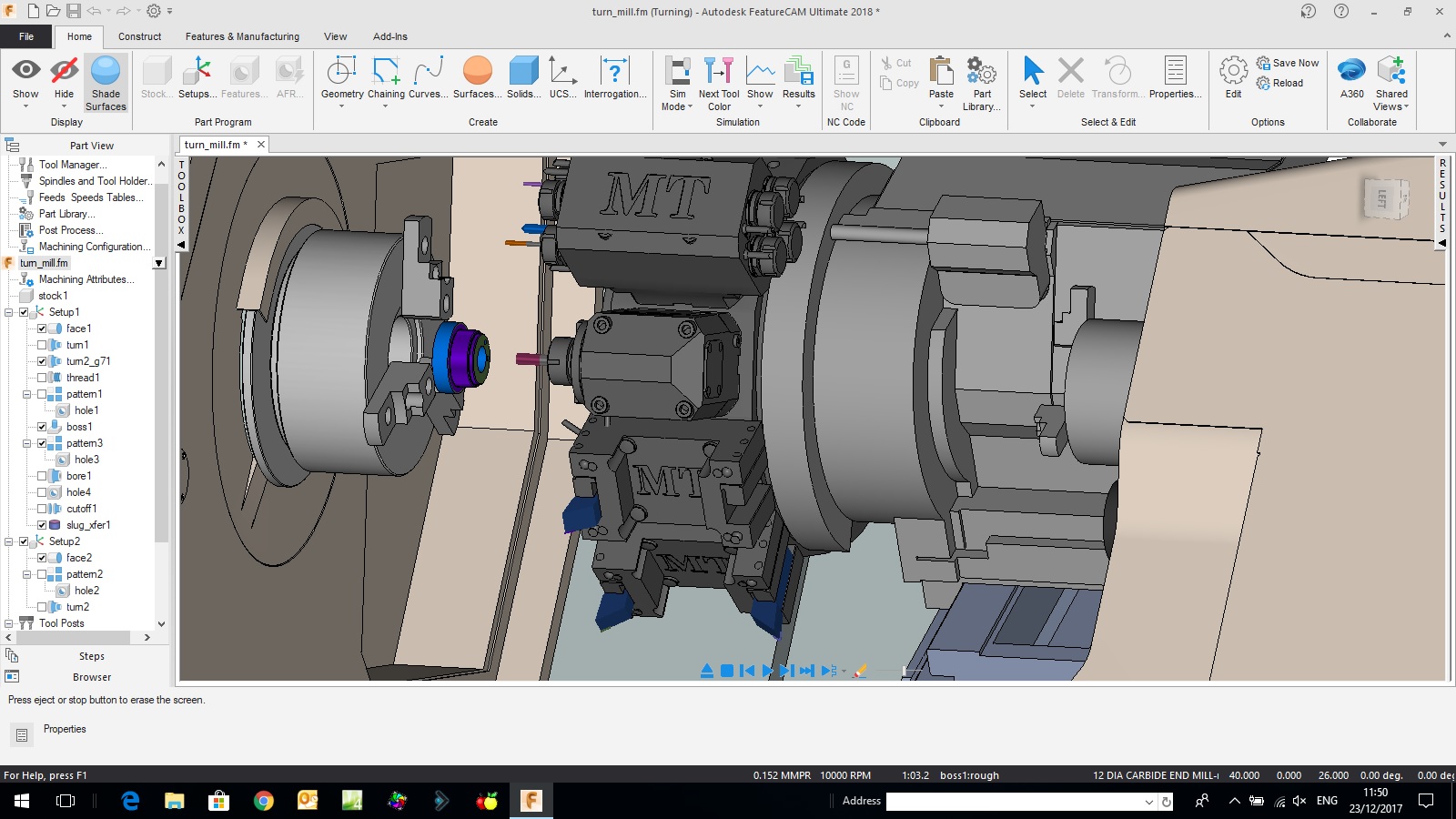

Machine Simulation - FeatureCAM provides complete simulation of the machine tool environment to identify collisions between the machine components, spindle, holder, tooling and part stock in order to avoid costly mistakes. In addition to machine simulation, FeatureCAM also offers centerline, 2D, 3D and RapidCut simulation modes.

Faster programming turnaround because you can simulate cutting motion ahead of time.

Avoid production delays because of a machine that’s down.

Avoid costly repairs to a crashed spindle.

Avoid cost overruns from scrapped workpieces.

General peace of mind.

Specific capabilities:

Simulate complex machine tools and toolpaths for smoother machine tool movements.

Warnings for holder collisions and gouge detection ensure no costly mistakes occur during the manufacturing process.

Realistic graphics show metallic part rendering and may be rotated during the simulation.

Import or build machine models with FeatureCAM’s Solid Modelling module or your own solid modeller, including jigs, fixtures and machine specific features.

Load toolpaths into different machine models to ensure you use the most appropriate machine to produce the part.

Support for multiple cores enables you to simulate your manufacturing process faster than ever.

Cursor arrow keys allow you to step through the simulation at your own pace.

Part compare allows for quality control prior to machining, preventing scrap and the need for reprogramming.

Start a 3D simulation at any stage of the machining process.

Telephone: 0116 267 5588